I spent two weeks at Brothers Make, a small business on the South Coast that turns 100% recycled plastic into useful products. They care deeply about sustainability and want to inspire people to see plastic waste differently. They also work with other companies to promote recycling and reduce waste.

During my time there, they gave me a challenge: design a new product for their online shop. It needed to fit with their current range of colourful, everyday items. Plus, it had to work with their injection moulding machine, which is how they make their products.

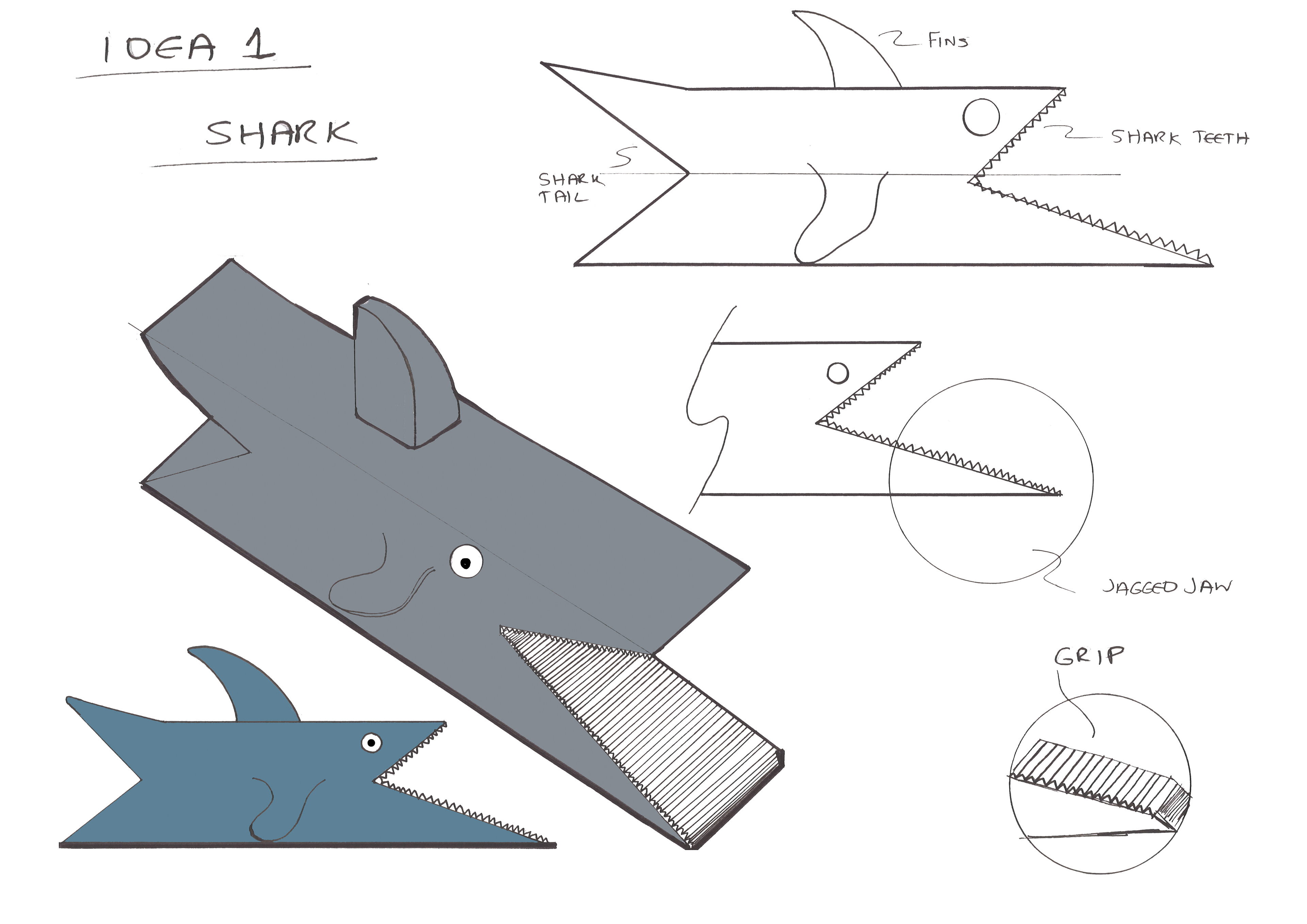

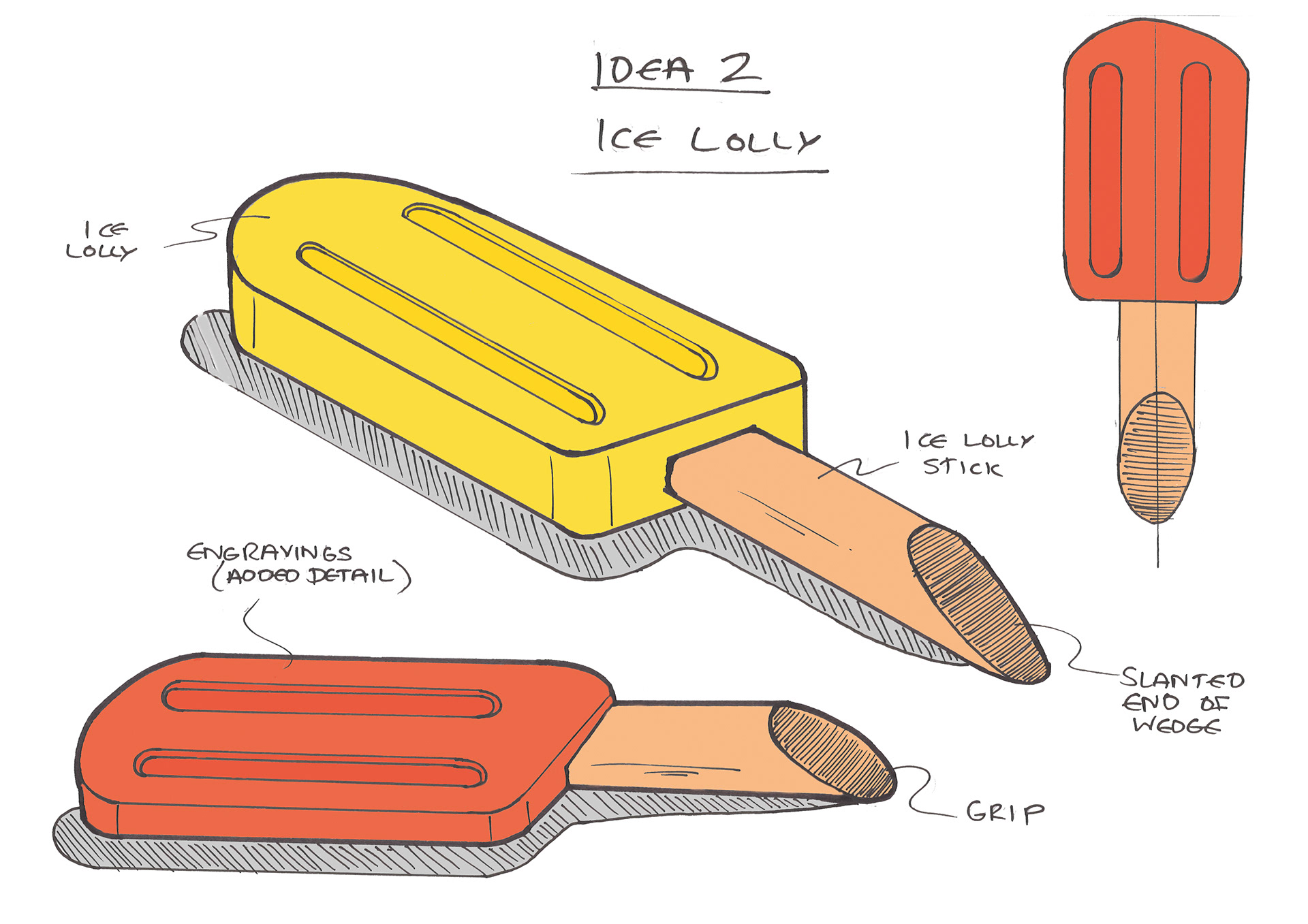

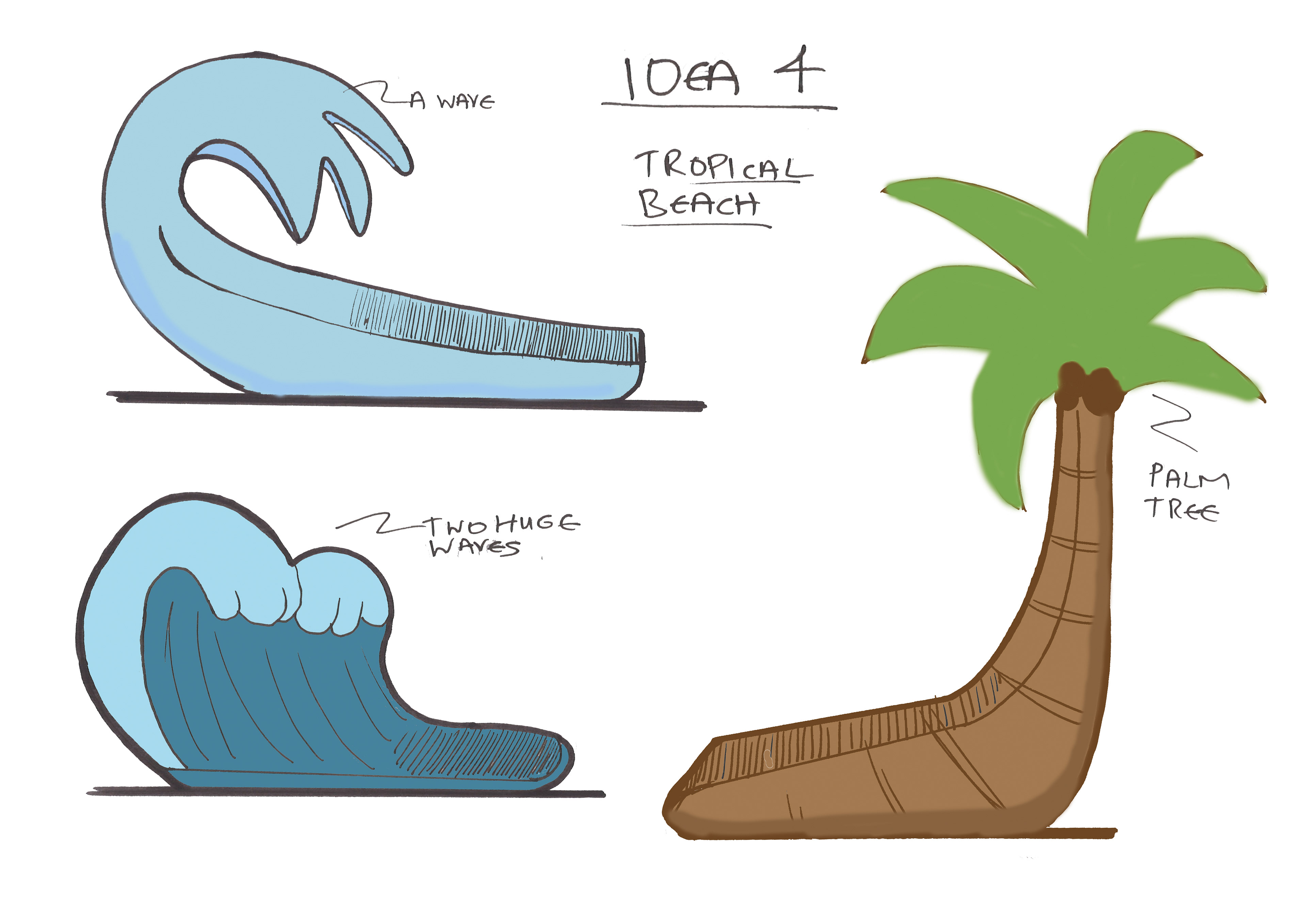

I came up with a fun door wedge for kids' bedrooms. It’s not just practical—it’s full of personality and charm. For the design, I looked at animals, nature, and familiar everyday objects. The idea was to make something kids would find fun and appealing while still doing its job as a door wedge.

I decided to go with the ice lolly idea and started thinking of different designs. I kept noticing a pattern—lollies with bite marks or melting edges. That gave me the idea to shape the door wedge like a melting ice cream or a bitten lolly.

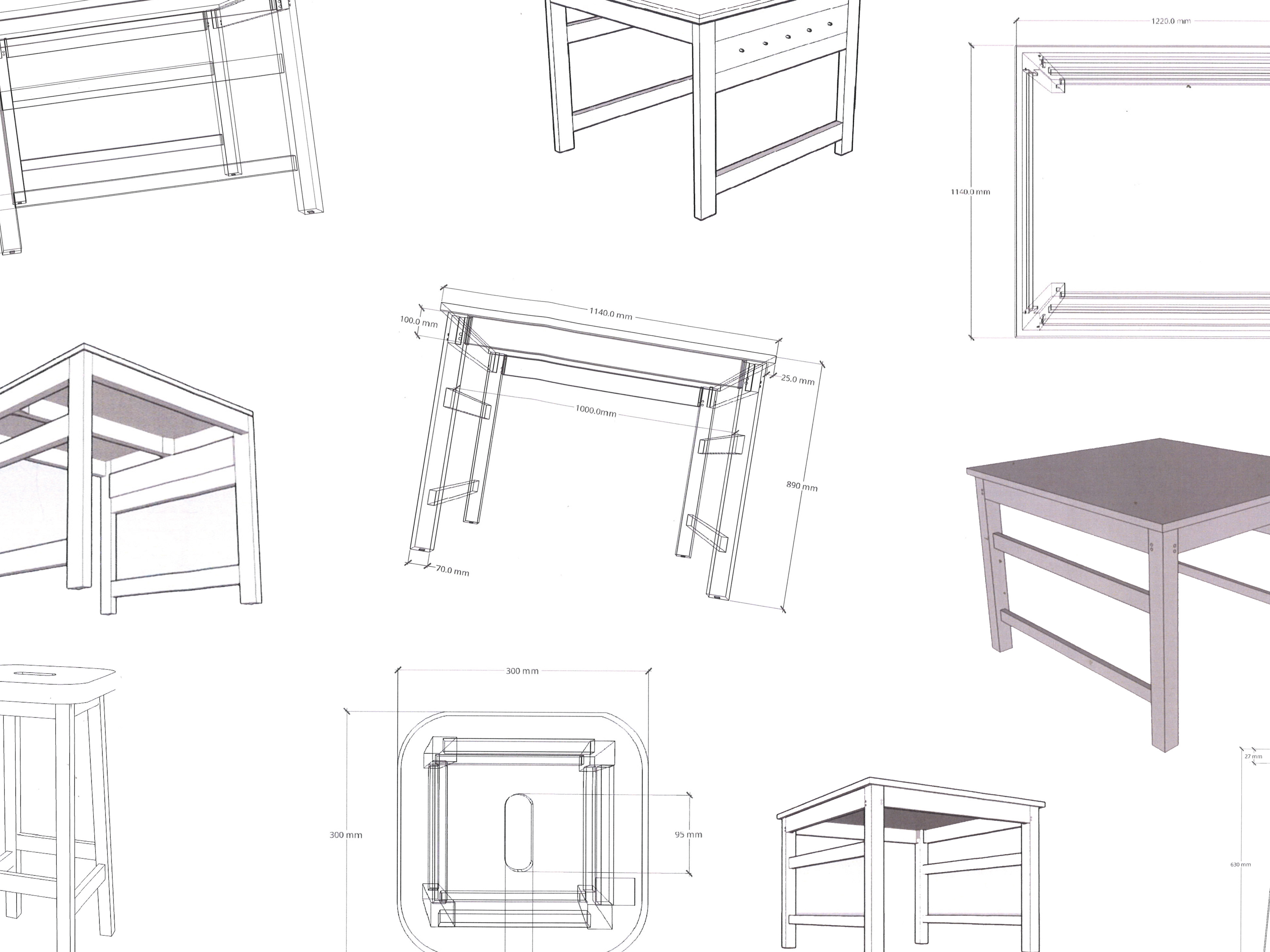

I worked on a lot of ideas using CAD and 3D printing to make prototypes. I tested them and got feedback to spot any problems. One idea was to angle the lolly downward into a melting puddle. But it ended up looking like a spade stuck in sand and didn’t slide under a door well. Another idea was a lolly lying flat with a puddle in front. But it didn’t have enough slope to work as a doorstop.

The outcome is a melting ice lolly that leans slightly off the ground and smoothly slopes into a shape that acts as a perfect door wedge.

The fun part is how it looks in action. It's like someone dropped a lolly on the floor and slid perfectly into place under the door. It's great for children's classrooms or bedrooms and adds a bit of humour, almost as if someone left it there as a cheeky joke or was playing an impractical prank on someone.

It was a great experience to work in a creative space and bring a real design project to life. I even got to present it to the team.

I took part in the whole manufacturing process—cleaning and shredding plastic, injection moulding, and packaging the products for sale. I also learned about the business side of things, like market potential and the costs involved in making my design.